Stone Powder Synthetic Paper for Supermarket

Categories:

Product introduction

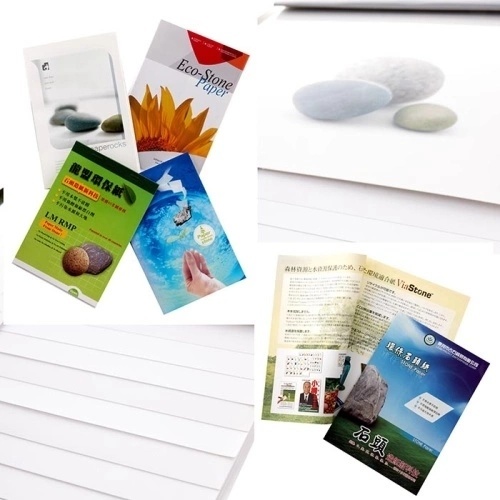

Stone paper is a kind of new material, which is between paper and plastic. That is to say, it can replace part of the traditional functional paper and professional paper, and can also replace most of the traditional plastic packaging. And it has the characteristics of low cost and controllability degradation, saving a lot of cost for the users without producing any pollution. From the perspective of replacing the part of the traditional paper, it can save a lot of forest resources for the society and reduce the secondary pollution generated in the papermaking process. From the perspective of replacing part of the traditional plastic packaging, it can save a lot of strategic resources oil for the country (using 1 ton can save oil 2.3 ton). Degradation is available after using the product, without producing secondary white pollution. Environmental protection of new materials --Stone paper, which draws from a very wide range of products. And the product upgrades, technology upgrading and the space of application are extensive. It is a very strong vitality, with a prosperous industry.

Synthetic paper is made of raw chemical materials such as olefins and some additives, with the soft texture, strong tensile strength, high water resistance, light and heat resistance, a chemical corrosion resistance and good permeability, making environment pollution impossible. It is widely used in high-level works of art, maps, pictures, high-end books and other printings. Making the semi-finished paper products by synthetic polymer materials (such as polyethylene, polypropylene, etc.) with the method of pulling film (film or blown film). And then using the chemical or physical way makes it paper-based, for example, the sand-based can increase the opacity and handling the surface with the chemical can get the hydrophobic property and so on. Another synthesis paper products can be made by the synthesis of pulp after being dealt. Synthetic paper is of high tensile strength, high tear strength, good insulation properties, optical properties and excellent wet strength.

Market Of Synthetic Stone Paper

The synthetic paper was first developed by Japan, the United States, France, and England in the 1960s and developed rapidly. At present, there are dozens of companies in the world producing synthetic paper, and the scale of production is generally 1000 tons-10000 tons per year. The production of synthetic paper is mainly polypropylene. The process includes the rolling method and the extrusion drawing method. Japan is the first country in the world to develop the synthetic paper, and it's still in the leading position. In the United States, calcium carbonate is added to the polypropylene film on the basis of the tensile method, which greatly reduces the cost and improves the competitiveness. Because of the high price of synthetic paper, it's difficult to compete with ordinary paper. Reducing costs means a lot to improve competitiveness.

FACTORY WORKSHOP

Certificate of Honor

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

FAQ

What are the methods for reducing the density and specific gravity of stone paper?

According to the current technology of domestic manufacturers, stone paper can already make the appearance and texture of traditional paper, but most of stone paper cannot reach the density and specific gravity of traditional paper.

How to reduce the density and specific gravity of stone paper through foaming technology?

Environmental protection materials, energy-saving technology, no pollution (no strong acid, no strong alkali, no bleach, no fluorescent agent, no water, no tree cutting).

The benefits of using stone paper?

We see many beautiful and exquisite iron cans and iron box packaging on the market, but do you know how the... printing on the iron cans and iron boxes is printed? Is there any difference between different printing methods? The most common printing process we use is transparent iron printing. The transparent iron printing of iron boxes refers to the direct printing of four colors or spot colors on the raw material of tinplate during the printing process. The corresponding printing process to transparent iron printing is through white magnetic printing.

What are the benefits of stone paper?

Environmental protection materials, energy-saving technology, no pollution (no strong acid, no strong alkali, no bleach, no fluorescent agent, no water, no tree cutting).

Online Message