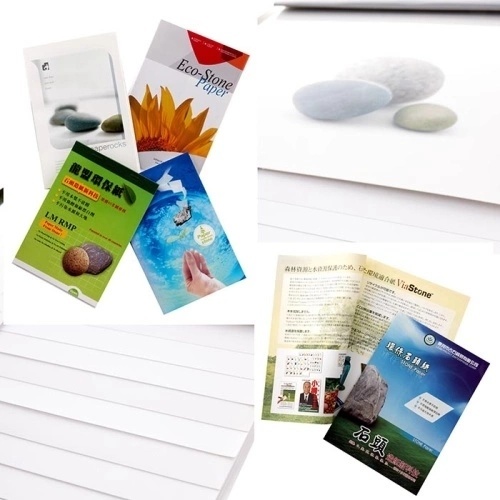

resistant to tear Eco-friendly stone paper

Categories:

Product introduction

Rich mineral paper/ board can be printed through most printing methods, which include offset, gravure, flexography, screen and rotary. Rich mineral paper/ board has advantages of pulp and synthetic paper. It can be easily printed by using common printing machines and methods. Moreover, it has water resistant properties like the synthetic paper. We recommend the following when printing on rich mineral paper/ board (RPD and RBD). Please note the following is only a guide. Settings can still vary between different printers and operators.

Regular ink and soy ink are adequate for rich mineral paper/ board print.

Printing speed is approximately 7500 ~ 8000 sheets per hour for dark / solid color, more than 9000 sheets for lighter colors.

Water feed is [Set 21 and Ratio 115].

Ink feed is [Set 40 and Ratio 116].

Drying powder is level 4~6, depending on the artwork.

RPD and RBD's surface immediately dries after print. For rich mineral paper/ board (RPD & RBD) to fully dry and ready for further prints or processes please allow approximately 1 hour after light color prints or 6 hours after dark color prints.

When stacking printed paper, please place separating plates as required.

To minimize static, please maintain at least 40% relative humidity. Anti-static equipment such as ionizing air units at the feeder and/or delivery is preferred but not essential.

Please trim 4 sides of the paper where higher printing and conversion precisions are required.

FACTORY WORKSHOP

Certificate of Honor

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

FAQ

What are the methods for reducing the density and specific gravity of stone paper?

According to the current technology of domestic manufacturers, stone paper can already make the appearance and texture of traditional paper, but most of stone paper cannot reach the density and specific gravity of traditional paper.

How to reduce the density and specific gravity of stone paper through foaming technology?

Environmental protection materials, energy-saving technology, no pollution (no strong acid, no strong alkali, no bleach, no fluorescent agent, no water, no tree cutting).

The benefits of using stone paper?

We see many beautiful and exquisite iron cans and iron box packaging on the market, but do you know how the... printing on the iron cans and iron boxes is printed? Is there any difference between different printing methods? The most common printing process we use is transparent iron printing. The transparent iron printing of iron boxes refers to the direct printing of four colors or spot colors on the raw material of tinplate during the printing process. The corresponding printing process to transparent iron printing is through white magnetic printing.

What are the benefits of stone paper?

Environmental protection materials, energy-saving technology, no pollution (no strong acid, no strong alkali, no bleach, no fluorescent agent, no water, no tree cutting).

Online Message